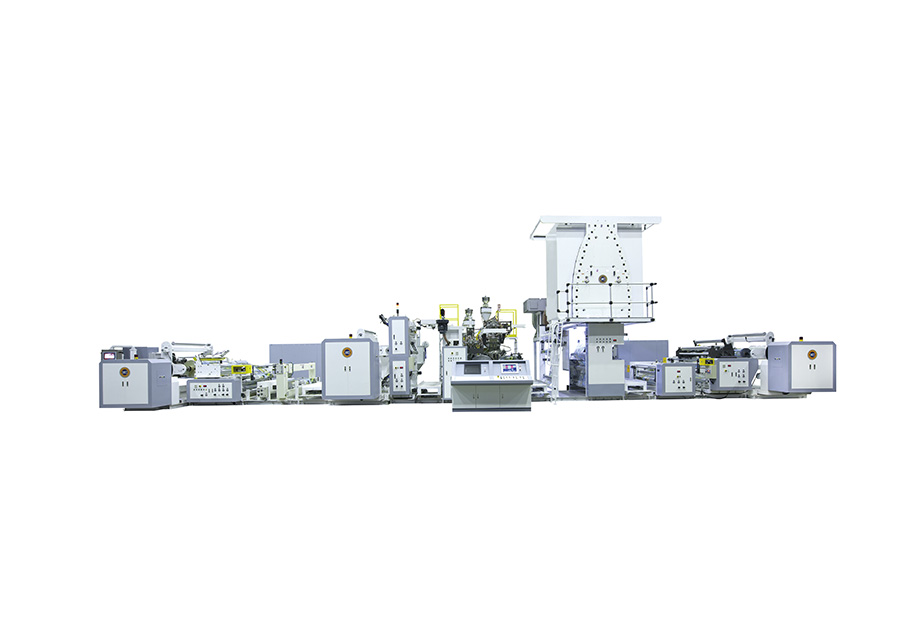

| Resin |

LDPE or PP or EVA or EAA or SURLYN |

|

Substrates for main unwinder |

|

| Material size |

800mm dia. x 1250mm width and min. 800mm |

|

Substrates for sandwich unwinder |

|

| Material size | 800mm dia. x 1200mm width |

| Metalized PET film | 8 - 10 micron |

| Lamination thickness | Coating thickness 9.1 GSM as standard, |

| Mechanical design speed | 350M/min |

| Unwinder | 2 drums turret system with EPC |

| auto splicing, auto cut, fully automatic control system | |

| Tension range | 3 - 30 Kg-f |

| Primer coating and dryer unit | |

| Extruder A | 65mm dia. screw, L/D=32:1 |

| Main drive | 50HP AC motor with vector inverter control |

| Extruder B | 90mm dia. screw, L/D=32:1 |

| Main drive | 75HP AC motor with vector inverter control |

| Extrusion capacity | LDPE : 250 kg/hr |

| 3 layer feedblock | Cloeren, USA |

| Co-Extrusion T-die | Cloeren, USA |

| Lamination unit | 3 roller type |

| Sandwich unwinder | 2 drums turret system (Manual tension) |

| Tension range | 3 - 30 Kg-f |

| Winder | 2 drums turret system with pre-run |

| auto splicing, auto cutting system | |

| Tension range | 3 - 30 Kg-f |

| Electric control panel | |