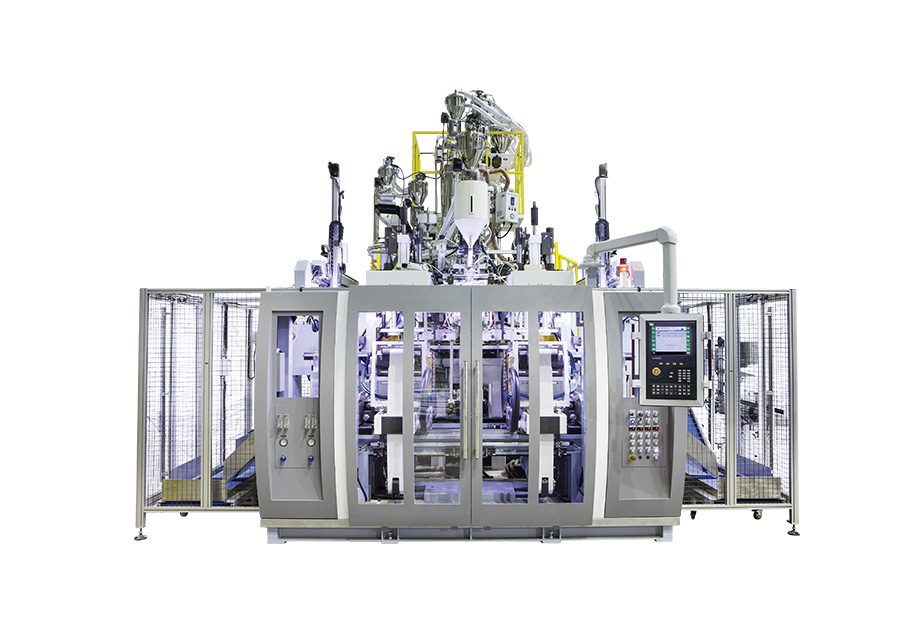

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle

Double Head, Double Station

HDPE bottle blow moulding

machine

| Resin |

HDPE, MFI=10 |

| Products |

20-30L jerry can, 20L: NET 1.5kgs/Gross:2.1kgs |

| production |

120 pcs/hr |

| Driving motor |

Exturder 55MM/75MM/55MM |

| Extruder |

55MM mm dia., L/D=30:1 |

| Output |

300kg/hr |

| Head design |

3 layers Single Head |

| Oil hydraulic motor |

40HP X 4P + 3HP X 4P Induction motor with hydraulic pump |

| Clamping plate ( H x W ) | 720 mm (H) x 550 mm (W) |

| Clamping force | 30 tons (300 KN) |

| Clamping stroke | 480MM - 1000MM |

| Mould thickness | 500 MM |

| Carriage shuttle stroke | 920 mm |

| Tonnage pressure | 180kg/c㎡(max.) |

| Postcooling | Two station, one is combined with deflash position; |

| Deflash | Top/bottom and handle deflash |