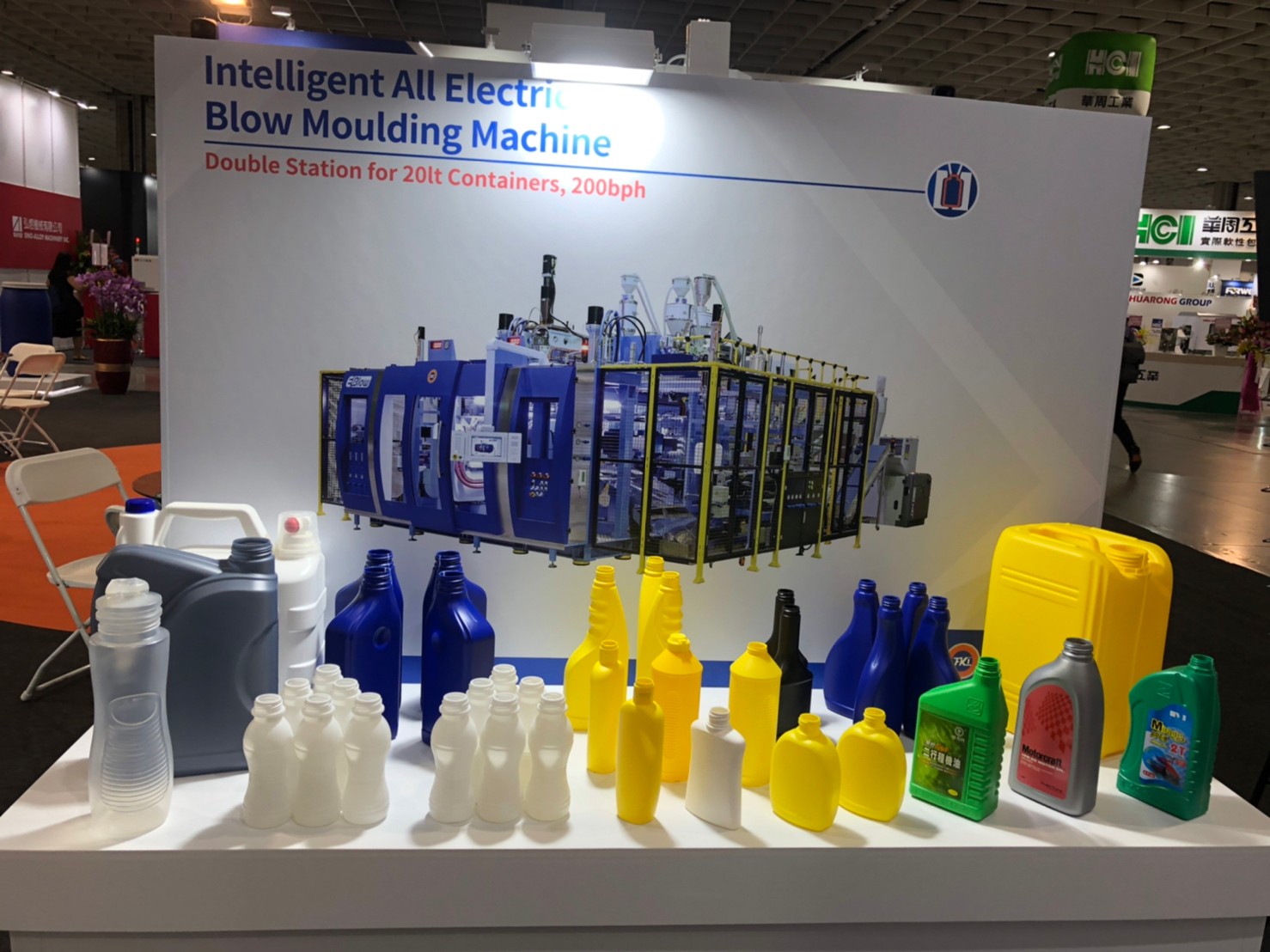

The All Electric Blow Molding is a true realization of green production. This is the reason why FKI present again their All Electric Blow Molding Machine at K Show 2022, but this time they have come up a new model with 3 layer, single station.

Advantages and features that are presented:

l True Eco Friendliness: low energy consumption, less carbon footprint, zero pollution, less maintenance cost, and 25% - 35% less on energy can be saved by All Electric machine compared to traditional hydraulic one.

l Achieving 3R: the Reduce, Reuse, and Recycling the Plastics.

This model is capable to process more recycled grade or PCR in the middle layer of 3 layer canister. 30% weight reduction can be achieved without compromising the quality from the drop test and stacking stability. Also, the model offers an improved design on product shaping. With 3 layer structure, 60% of master batch can be reduced, meaning also a tremendous saving on the total use of plastics materials in a year.

In addition, when less plastics materials are being used per canister, it produces much less heat and enable a faster cooling cycle which ultimately increases the production rate. And on FKI’s Industry 4.0 Smart Manufacturing Control System, all the production data can be collected for a more precise analysis and optimizing the production solutions in several ways, such as:

l Plastics materials consumption in virgin grade, regrind grade, master batch.

l Energy consumption data by hour/month/year.

l Processing condition with alarm signals in real time.

l Preventive maintenance instructions to keep the machine always at high working efficiency.

Also, this FKI smart system is complied with the digital communication protocol to deliver accurate readings and using Oracle MySQL open-source to minimize to offer a maximized programming capacity. Besides, this Client/Server version can link up to 5 remote users at same time.