Congratulations to Fong Kee International! Winning two awards this time at Taipeiplas 2018. The first being the design award for the Blow Molding Machinery category and the second being the machine with the best overall design beating out machinery from all categories!

Based on the market demand for large tonnage all-electric blow molding machines, Fong Kee started to carry out the data collection and design concept of large-ton all-electric blow molding machine in December 2016, and set the development spindle: “eBlow T20s” at the end of January 2017. With the maximum specification clamping force of 250kN, the largest product 20 liter stacking barrel, and the single clamping

die table with a maximum output of 130pcs/hr,these specifications are the most close to the actual market demand, and the most economical for design and manufacturing costs.

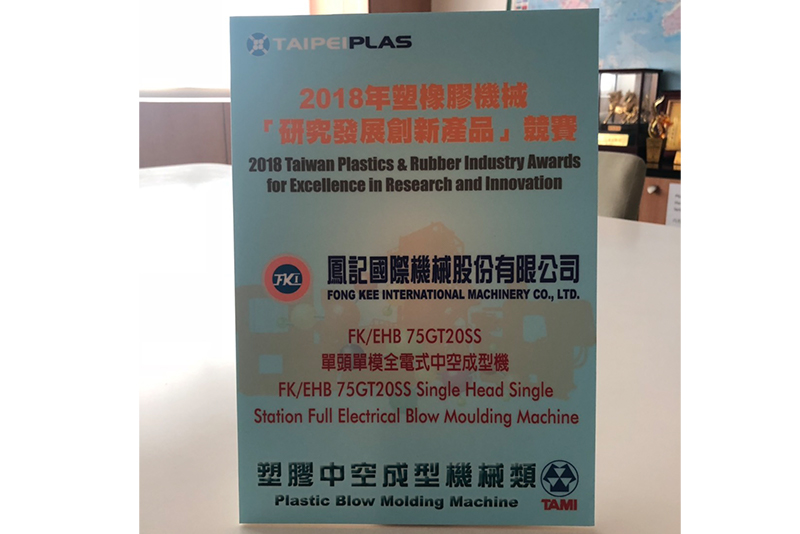

Award Winning Products:

Award Winning Products:

Single Head Single Station Full Electrical Blow Moulding Machine- FK / EHB 75GT20SS

For 20 liter Jerrycan, Advantage/ Efficiency: 40-50% Energy saving, 20-25% Production rate increase 25-30% Dry cycle faster 20db Noise level reduce 0% ollution Industry 4.0 The smart manufacturing.

Apart from the PLC and HMI control system being used, SCADA system is available to link thru internet as to collect all the data and be monitoring from distance, such as office computer personal PC or mobile for machine. With long term production, all data can be collected for further analysis to improve the efficiency, cut down the cost and bring more profit.